Words by Jamie Burnett | Photos by Dwight O’Neil

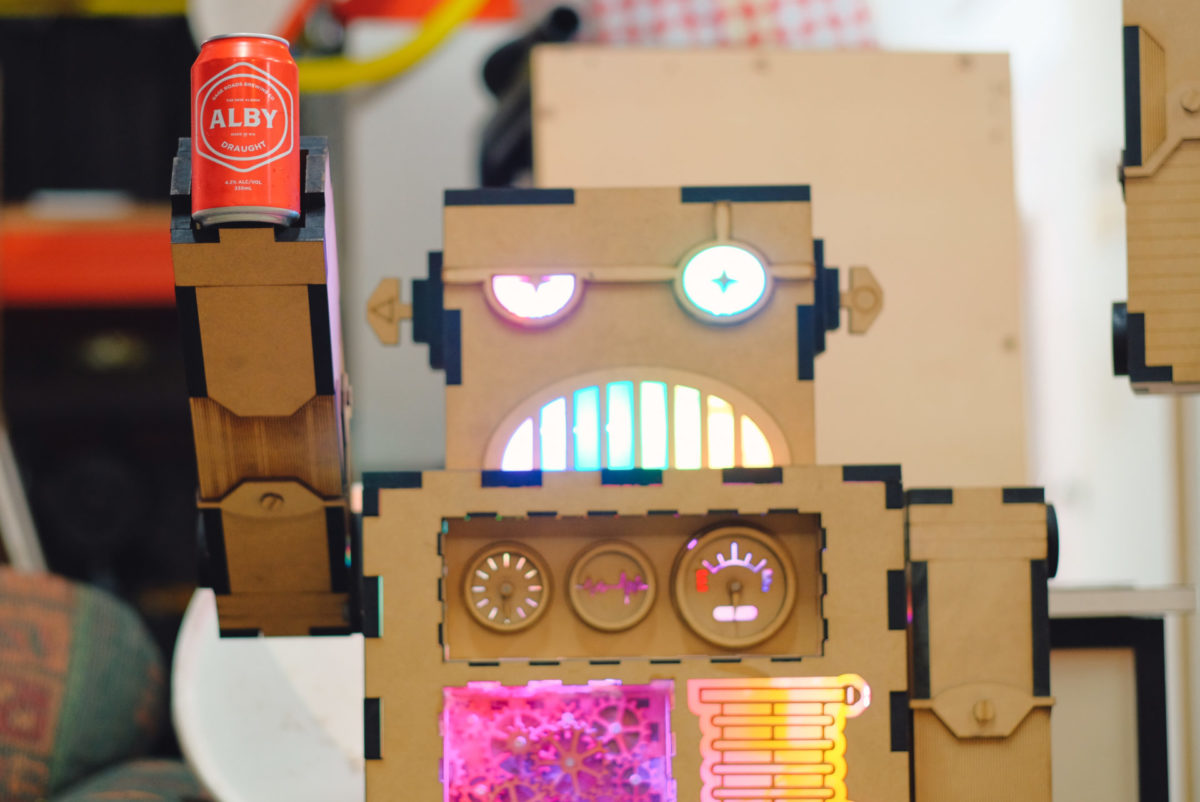

It’s the type of shed every DIY wannabe wishes was theirs. And the good news is, it can be. Firstly it’s big… real big. And it’s choc-full of toys. Amongst the more standard tools like sanders, saws and drills, there’s plenty of speciality gear. Near the back there’s “Big Red” (the big red coloured laser cutter). “Little Red” (you guessed it) is the smaller laser-cutter. There’s a design room with 3-D printers and top-end software. While next door you’ll find an electronics room that looks like some kind of communications bunker. It’s wall to wall with screens, speakers and wires. And in between that, there’s the band room. It’s soundproofed and ready for rehearsal. Essentially Perth Artifactory is pretty cool and open to all.

The idea for the Osborne Park community workshop started more than a decade ago, and now a range of makers from across Perth share the space to create almost everything.

“This place started in 2009 in the lobby of a Hungry Jacks with the founders pooling together their tax returns… they rented a house in Mt Lawley in 2011 and then moved to this warehouse (current Osborne Park site) and shared the space. Now we’ve expanded to the point where this site is all us,” says deputy treasurer Fletcher Boyd.

“We’re Perth’s only public maker space. We’re a community workshop where people can come, work with a range of different tools, learn new technologies and work in a collaborative environment to build new ideas in ways that you can’t do anywhere else.”

While Perth Artifactory has grown in size over the last decade, its core is still about community, sharing ideas and helping out. There’s a range of different makers who come here, with a diverse range of skills. There’s woodworkers, metalworkers, robot creators, laser cutters, leather makers and musicians – and that’s just scratching the surface. Fletcher says that melting pot takes ideas and skills to interesting places.

“A lot of what happens here is inspired by the people that come here getting together. That leads to new ideas and creations. Our youngest member is 16, but we have people come through with their kids to start making at just six or seven. Other guys bring in their dads and I bring my grandfather occasionally and we work on woodworking projects.

“We’ve not only got a massive spectrum in ages, but in professions too. We have artists, engineers, students, mathematicians, sculptors and all sorts of different people that want to work on things.”

Fletcher then points to a whiteboard in the corner.

“You see that whiteboard? There’s a bunch of mathematical equations on the back. They were put up by a PHD student. Throughout the night other people here were jumping on the board and helping solve the problem. You don’t get that anywhere else.

“Personally, I’ve taken people through from learning how to use a hammer and going up to learning how to using industrial laser cutters… they’ve gone from no skills to being quite an accomplished makers over time and all through the help of people here.”

Like many members, Fletcher joined because he wanted to get on the tools and get around others who craved the same.

“I wanted to do more things with my hands and I was looking for that community aspect. I wanted to connect with other people who were into the same things. I started building a server rack but I ended up standing in front of a laser cutter all night, entranced by cutting random geometric shapes after a member had spent 30 minutes showing me how to use the machine. From there I went into learning how to use and maintain these machines… that really fascinates me and there’s nowhere else I could learn to do that.

“Apart from the community, the biggest thing I’ve got from this place is the exposure to a range of different technologies… and so many different ways of thinking and viewpoints. You have a problem presented here and five different members will come up with five different ways to solve it… that continued exposure to that melting point of ideas has been fantastic.”

In its tenth year, Perth Artifactory has received a welcome boost, announced as the latest ALBY Made Community Arts grant recipient. The community group will receive a $1000 grant to help provide new specialist equipment.

“The majority of funds are going toward upgrading our design room… it’s a space where people will have access to 3-D printers and specialist software.

“We run on a shoe-string budget and this type of grant is what we need to maintain, expand and make the space better for everyone. We connect with so many different groups and subcultures… getting different makers and people together who want to hang out.”

To find out more about Perth Artifactory, head to their website here.